Animal Feed Process Control System

Simple and Intuitive

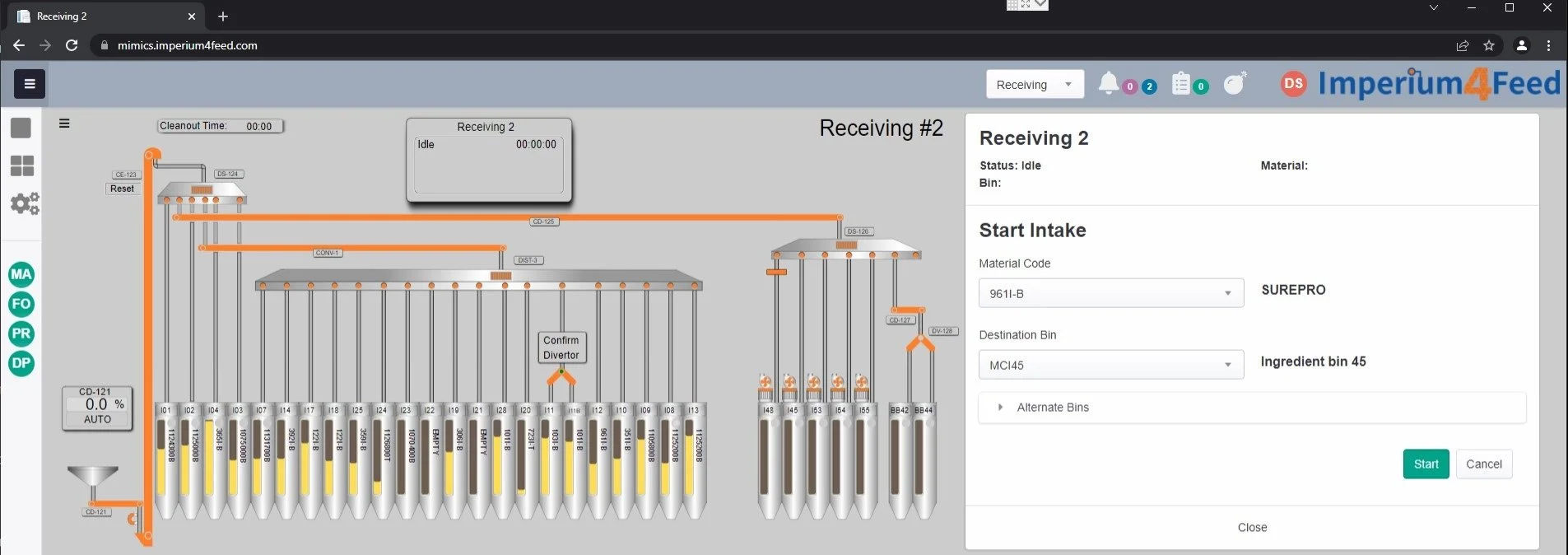

Imperium4Feed features a user-friendly graphical web interface accessible from any device with a browser, ensuring seamless management of feed mills and animal feed production. Designed for efficiency, its intuitive layout simplifies operations while maintaining full control over every production stage.

Hosted on a secure cloud-based server, Imperium4Feed ensures robust data protection while allowing remote access from anywhere. Unlike traditional on-premises systems, it leverages the power of the cloud for real-time updates, scalability, and seamless integration across multiple locations. With reliability, usability, and optimisation at its core, Imperium4Feed delivers a powerful, hassle-free solution tailored to the demands of modern feed mills.

Imperium4Feed Overview

-

24/7 Support and Built-in Redundancy to Minimise Downtime

-

Browser Based User Interface

-

User Configurable

-

Software For Life

-

Reduces Operator Workload

-

Expandable For Any Future Plans

Integrated Modules

OEE4Imperium is a web based performance monitoring system designed specifically for feed and grain plants. The system collects data from the Imperium4Feed local control system and displays OEE (Overall Equipment Effectiveness) and KPIs (Key Performance Indicators) on a web page. The data can be drilled down to reveal more detailed data. The web page can be accessed on a local intranet or exposed to the internet for global access. The system can be set-up with user security to prevent unauthroised access.

CMMS4Imperium provides a method of recording information on all site equipment which may be used as an aid to planned and unplanned maintenance. It also provides a means of storing supplier information and sub-assemblies in stores. If linked to an Imperium4Feed control system, equipment run times and other totals such as the number of times a certain item has been started are updated automatically; therefore maintenance schedules are automatically updated too. Equipment faults can be reported by the operator by clicking on the item which in turn automatically creates a maintenance task.

Plan4Imperium is designed to simplify the process of scheduling orders for production by visually displaying the production programme on a timeline and highlighting any potential problems. Plan4Imperium makes scheduling and planning simple and quick, prevents scheduling mistakes, warns of orders which are going to be late and minimises flush batches and die changes.

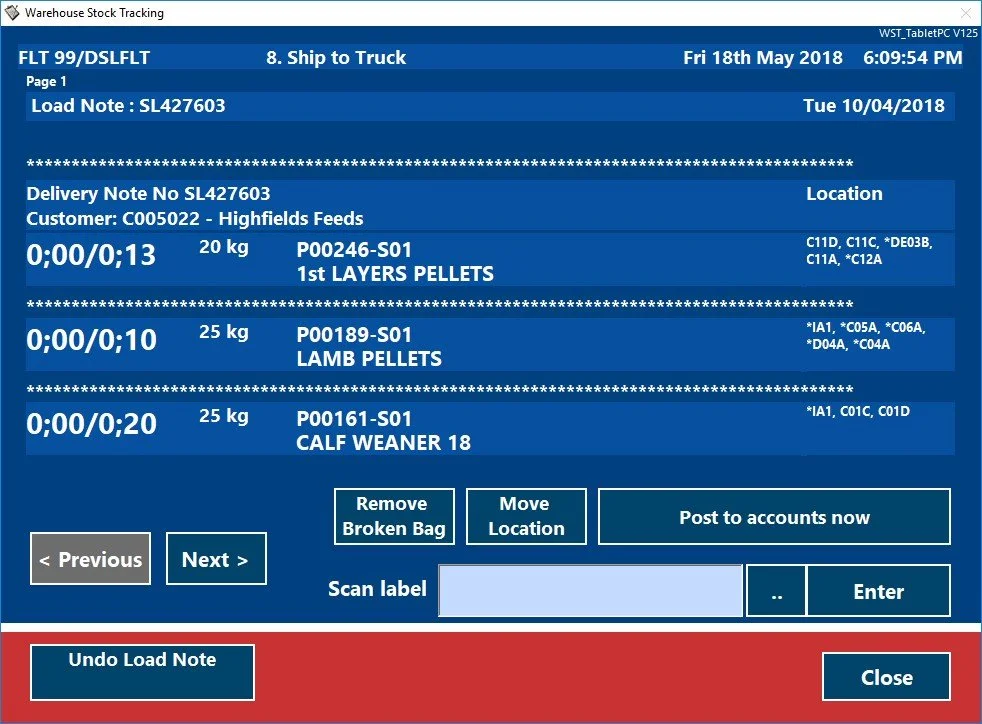

The Warehouse Stock Tracking option is simple to operate and yet provides substantial benefits. Every time a pallet is produced, a barcoded ticket is printed and stuck onto the pallet. When a truck arrives to collect a delivery, a wireless tablet PC is used by the forklift truck (FLT) driver. After entering the order number, the FLT driver wands the barcode of the pallets or part pallets collected. Codes and stock levels are instantly checked, preventing incorrect operations such as shipping the wrong pallet or missing items. A complete and accurate stock record is always maintained, and details of all deliveries are logged. A variety of reports and printouts are available as standard. The system works with pallets of small bags, big bags, raw materials, finished products, packing materials and consumables - whatever you have in your warehouse.

Make An Enquiry

Fill in the form to learn more about our Imperium4Feed process control system.